Robotic Process Automation Applications

CIM SYSTEMS is a leader in robotic process automation solutions for streamlined manufacturing automation and efficiency.

CIM SYSTEMS has over 35 years of experience in robotics and industrial automation in all types of applications. We specialize in transforming manufacturing processes through advanced automation solutions. Discover how CIM SYSTEMS can streamline your operations with cutting-edge robotic technology tailored to your unique needs.

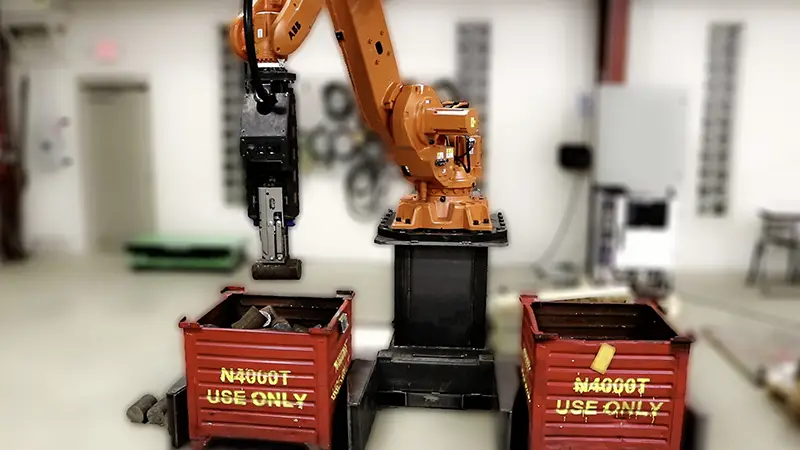

Palletizing / Depalletizing / Case Packing

We’ve helped customers across a range of industries improve their throughput and provide a safer workplace with robotic palletizing and depalletizing operations. Our robotic case packing cells enable quick and easy retooling when products change.

Material Handling

Whether it’s transmission housings, hamburger buns, or medical devices, robotic material handling is one of our core capabilities. Our expertise in this area results in highly versatile and efficient operations.

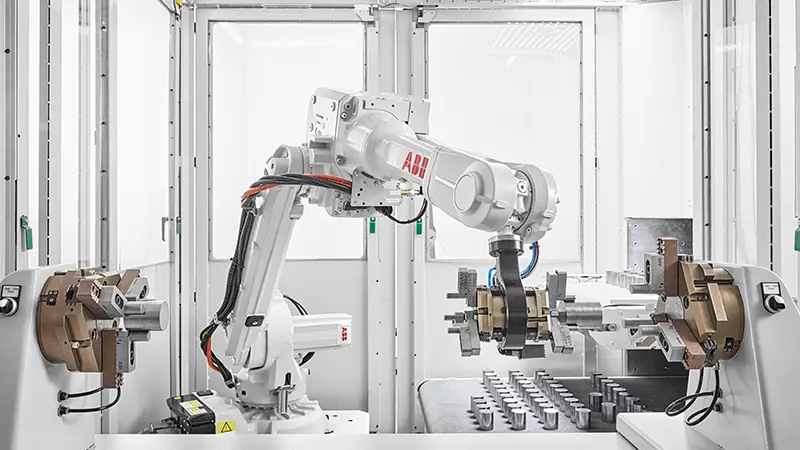

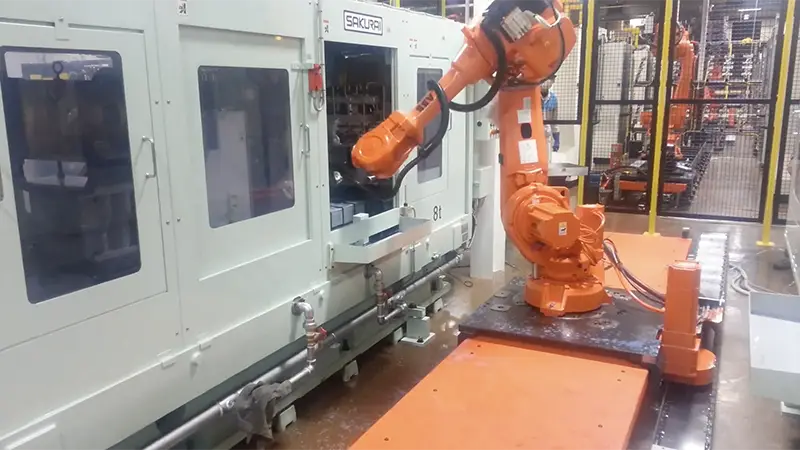

Machine Tending

We’ve been creating systems to load and unload CNC machines, die presses, injection molding machines, trim presses, forging presses, and other machines since our inception, and it’s still one of our core capabilities.

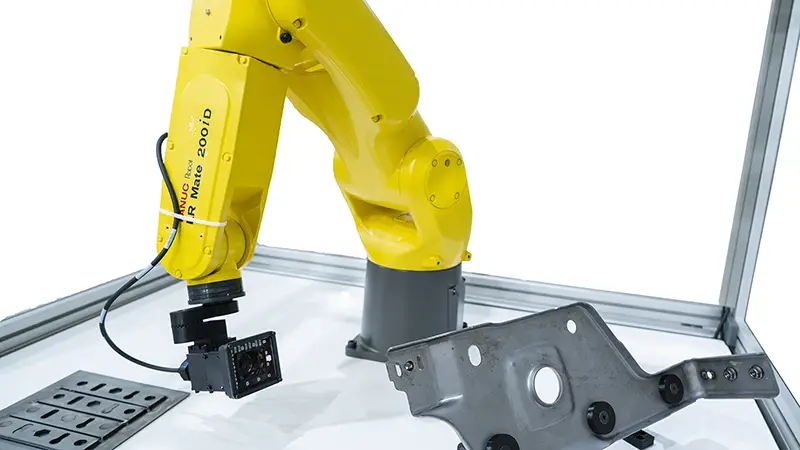

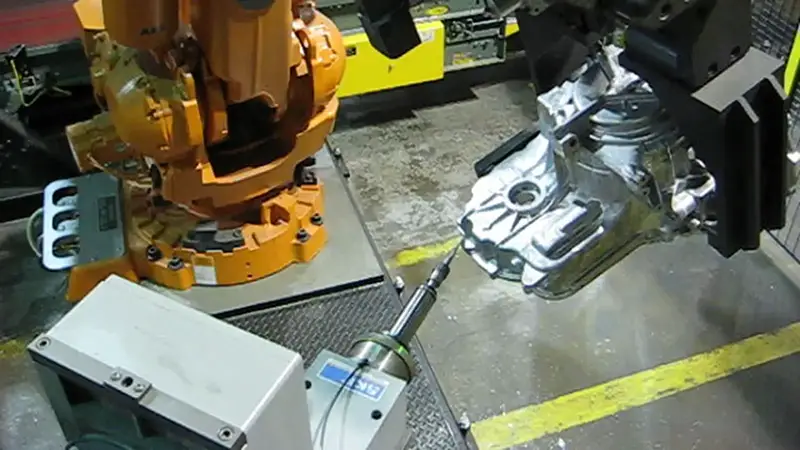

Inspection / Verification

We’re experts at integrating vision systems and/or test equipment with a robot’s motion to result in zero-touch, online or offline inspection of parts.

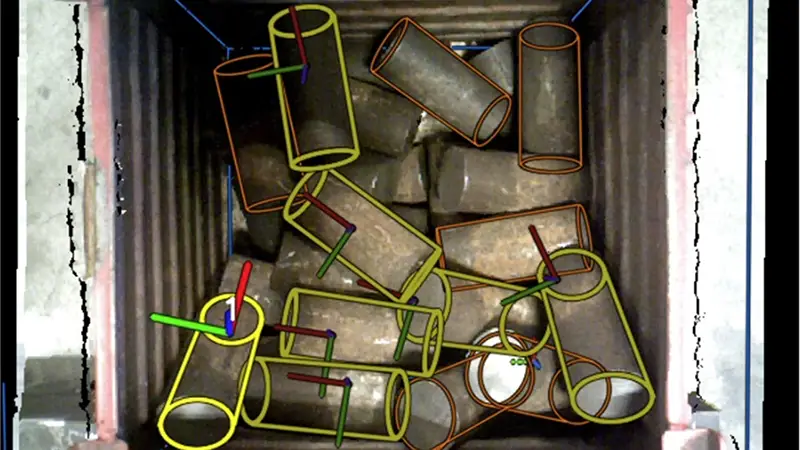

Random Bin Picking

We’ve pioneered new technology that uses 3D vision for bin-picking to replace manual loading or bowl feeders.

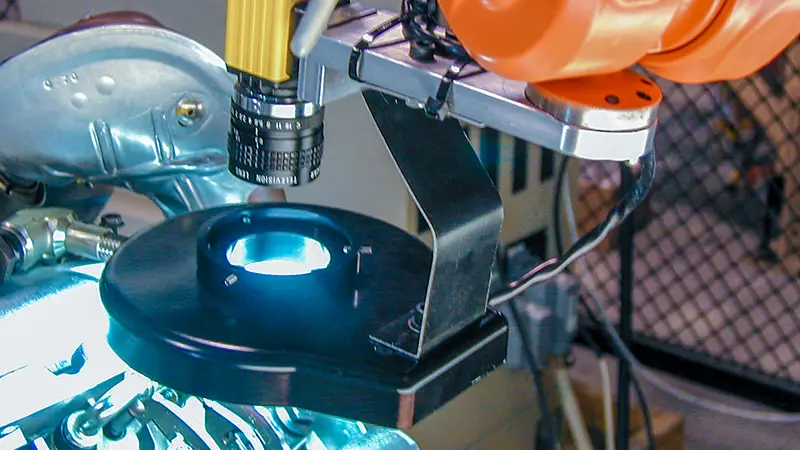

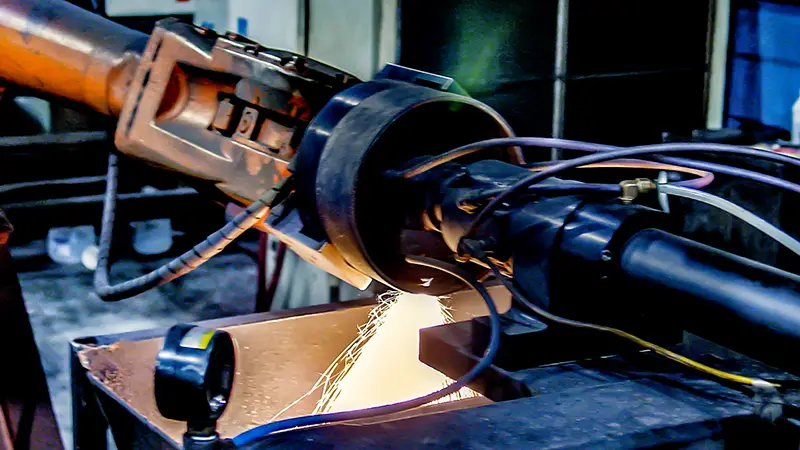

Material Removal / Polishing

Our robotic deburring, sanding, and polishing applications take the manual labor – and inconsistencies – out of part-finishing applications.

Dispensing

CIM SYSTEMS robots can apply sealants and adhesives quickly and consistently for maximum efficiency and minimal waste.

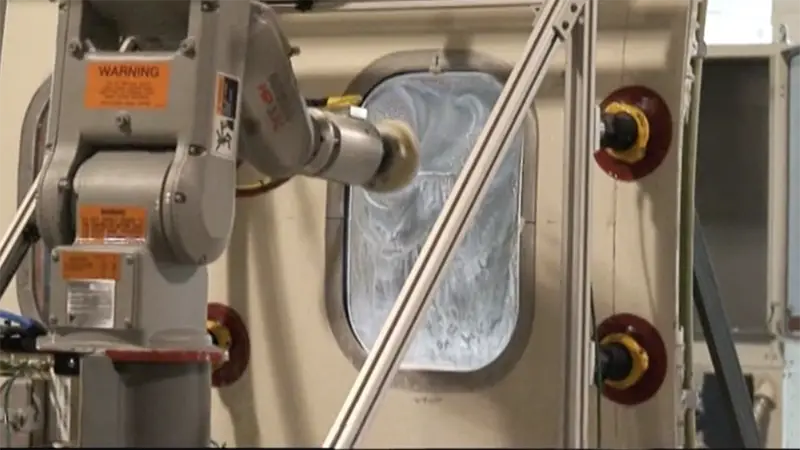

Coatings / Blasting

Plasma spray, media blasting, and powder coating applications can be tricky, but CIM SYSTEMS has both the experience and the expertise to provide reliable automation for these operations.

Cutting

By pairing a robot with a router, linear file, plasma torch, laser, saw, or other tool, CIM SYSTEMS has streamlined cutting operations for dozens of satisfied customers.

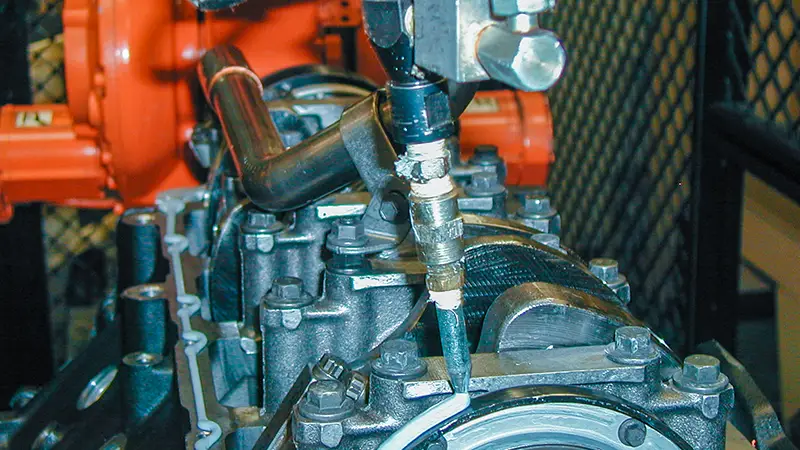

Automated Product Testing / Evaluation

CIM SYSTEMS has created both simple and highly complex robotic product and process testing systems that provide invaluable data for quality control, product development, and other research.

Track-Mounted Robots

Mounting a robot to a track can drastically increase its working area. We’ve found that adding a track can turn a 3-robot application into a single-robot system, dramatically reducing costs.

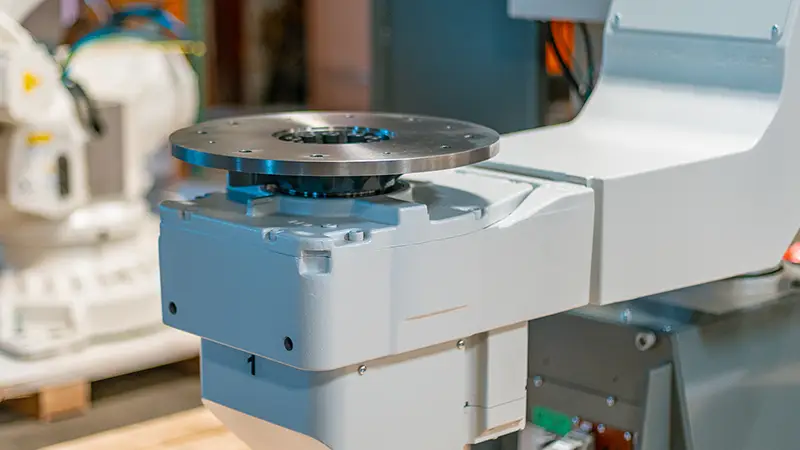

External Axes and Positioners

We frequently use positioners and external axes to increase a robot’s capabilities and allow external equipment to be controlled by the robot directly, allowing them to be fully synchronized.

Talk to a Robotic Application Engineer Today

Please fill out the form linked below or email us at [email protected] for more information about an application or to get help on your project.